A flexible power terminal for connecting busbars for energy transport was developed by Sefag Components AG for a customer. To minimize the scope and cost of the test, I was asked to use FEM simulations to verify that the clamp design met the thermal and mechanical specifications.

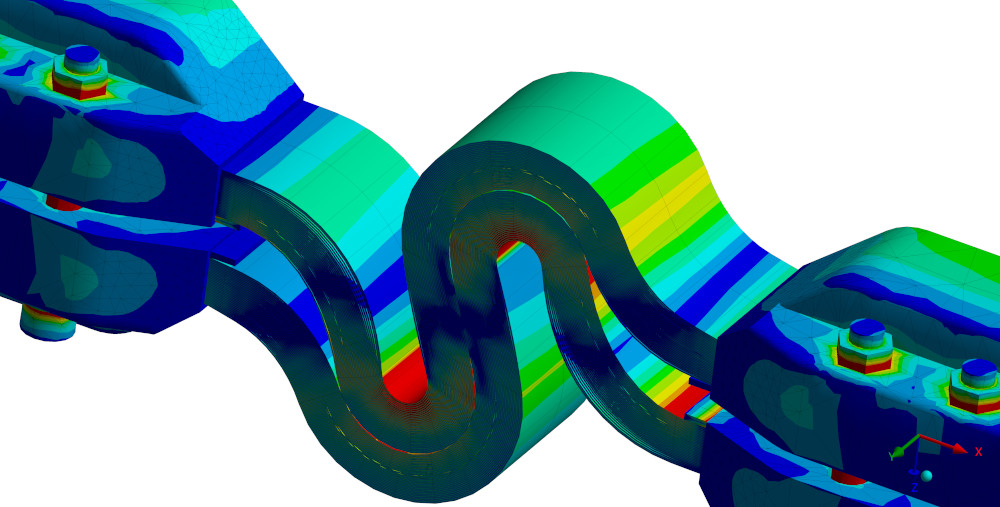

I modeled the terminal parametrically and used it to calculate coupled eddy current, thermal, and mechanical fields. Although the terminal is operated at line frequency, the eddy current effects were significant. My simulations showed that the equilibrium temperature at maximum current load and the mechanical strength in the event of a short circuit were within the customer’s specification.

The parametric model design also allowed me to optimize the geometry of the clamp and thus reduce manufacturing costs.

Targets and key figures

October 2016 – March 2017

Budget 50’000 CHF

Cooperation with four employees

Energy and electrical industry

Testimonial

The level of commitment was very high.”